MODEL LB100

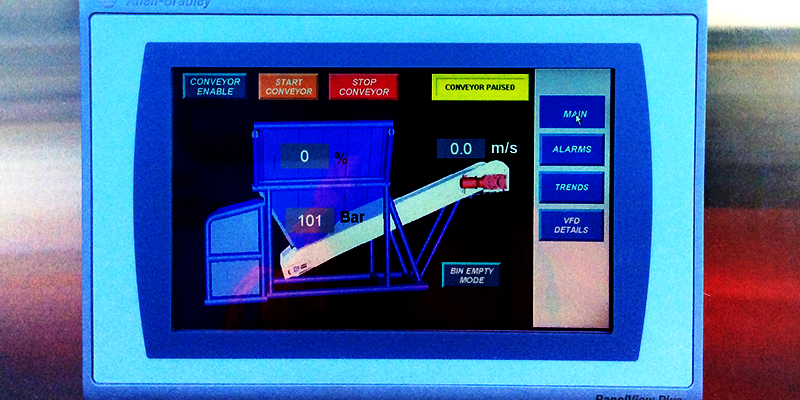

KIS Plant designed and manufactured a 100 tonne Loader Bin – Model LB100 for our client in NSW. The purpose of the Loader Bin was to allow the quarry site to load Primary Crushed Rock on to a CV110 Conveyor at a required rate. The Loader Bin was designed to be loaded with a WA700 or equivalent size loader. KIS Plant Loader Bins are designed for easy transportation and assembly on site. LB100 Loader Bin has been designed based on the following criteria:

- The material properties: minus 250mm primary crushed rock

- Production requirements: 1000 tonnes per hour

- Bin capacity: 100 tonnes

- PLC controlled

- Bin to be loaded with a WA700 size loader.